You’ll need the right blade to tackle metal cutting projects with your miter saw, but choosing among countless options can be overwhelming. Whether you’re working with aluminum, steel, or other metals, the blade you select will make or break your project’s success. From tooth count to coating technology, several key features separate average blades from exceptional ones. Let’s explore the top performers that’ll give you clean, precise cuts every time.

12-Inch Ultra Fine Finish Wood Cutting Circular Saw Blade

If you’re seeking professional-grade precision in your woodworking projects, this 12-inch, 100-tooth ATB TCT blade delivers ultra-fine finishes while handling diverse materials. With its 1-inch arbor and 4800 RPM capacity, it’s compatible with both miter and table saws.

Built from premium alloy steel with hardened tungsten carbide teeth, this chrome-plated blade features an ATB design that guarantees smooth, accurate cuts. You’ll appreciate its thin kerf and minimal tear-out when working with hardwood, softwood, plywood, or MDF. While most users praise its clean cuts and value, some report quality control issues, so inspect your blade carefully before use.

Best For: Professional woodworkers and serious DIY enthusiasts who need precise, clean cuts for fine woodworking projects requiring superior finish quality.

Pros:

- Premium construction with hardened tungsten carbide teeth for long-lasting performance

- Versatile compatibility with both miter and table saws

- Thin kerf design produces minimal tear-out and smooth cuts across various materials

Cons:

- Potential quality control issues with some units arriving damaged

- Higher price point compared to basic saw blades

- Requires careful inspection before use due to reported manufacturing inconsistencies

12 Inch Aluminum Metal Cutting Circular Saw Blade

The 12-inch aluminum metal cutting circular saw blade delivers precision and versatility for metalworkers and DIY enthusiasts tackling non-ferrous projects. With 100 teeth and a TCG grind, you’ll achieve smooth, burr-free cuts on aluminum, brass, bronze, and copper materials.

The blade’s premium alloy steel construction features an electrophoretic coating to prevent rust, while tungsten carbide teeth guarantee long-lasting performance. You’ll appreciate its compatibility with most 12-inch saws and the 2.8mm kerf that provides clean, efficient cuts. Users consistently report quiet operation and excellent edge quality, making this blade a smart investment for your metal-cutting needs.

Best For: Professional metalworkers and DIY enthusiasts who need a reliable blade for cutting aluminum and other non-ferrous metals with precision and clean edges.

Pros:

- Premium construction with 100 TCG teeth delivers smooth, burr-free cuts

- Durable alloy steel body with rust-resistant coating for long service life

- Versatile compatibility with most 12-inch saws and excellent for various non-ferrous metals

Cons:

- Mixed results reported for some specific cutting applications

- Premium price point compared to standard saw blades

- Limited to non-ferrous metals only, not suitable for steel or iron

12 Inch Aluminum Cutting Saw Blade (1 Inch Arbor)

Professional contractors and DIY enthusiasts seeking precision aluminum cuts will find exceptional value in this 12-inch blade with its 96-tooth design and TCG technology. You’ll get clean, burr-free cuts through various aluminum thicknesses up to 7/16 inch.

The blade’s super-density micro-grain carbide and tri-metal shock resistant brazing guarantee durability under extreme conditions. It’s compatible with major brands like SawStop, Jet, Dewalt, and Bosch 12-inch miter saws. The 1-inch arbor and ATB technology deliver clog-free performance, while the radical blade design resists impact and wear. If you need support, you can access quality customer service beyond Amazon’s return window.

Best For: Professional contractors and serious DIY enthusiasts who need precise, clean cuts on aluminum materials and work frequently with non-ferrous metals.

Pros:

- Superior 96-tooth design with TCG technology delivers exceptionally clean, burr-free cuts

- Versatile compatibility with major brand saws and ability to cut various aluminum thicknesses

- Durable construction with micro-grain carbide and tri-metal shock resistant brazing for long life

Cons:

- Limited to non-ferrous metals and plastics only

- May struggle with materials thicker than 7/16 inch

- Higher price point compared to standard multi-purpose blades

DEWALT 12-Inch Miter Saw Blade 2-Pack (DW3128P5, DW3123)

Woodworkers seeking versatility will appreciate DEWALT’s 12-inch miter saw blade combo pack, featuring both an 80-tooth and 32-tooth blade for diverse cutting needs. You’ll get clean, precise cuts on hardwood, softwood, plywood, and chipboard thanks to the tungsten carbide construction and thin kerf design.

The wedge shoulder design strengthens the blade tips, while computer balancing reduces vibration for smoother operation. You’ll notice the 80-tooth blade excels at fine crosscuts, while the 32-tooth handles general-purpose cutting. Though durability varies with use, these blades deliver professional-grade performance for both beginners and experts.

Best For: Professional woodworkers and DIY enthusiasts who need versatile blades for both fine finish work and general-purpose cutting on their miter saws.

Pros:

- Combination pack offers versatility with both fine-cutting (80-tooth) and general-purpose (32-tooth) blades

- Tungsten carbide construction and thin kerf design ensure clean, precise cuts with minimal material waste

- Computer-balanced plate reduces vibration for smoother cuts and better finish quality

Cons:

- Some users report faster wear than expected with heavy use

- Package may be misleading as some expect two 80-tooth blades

- Premium price point compared to basic blade options

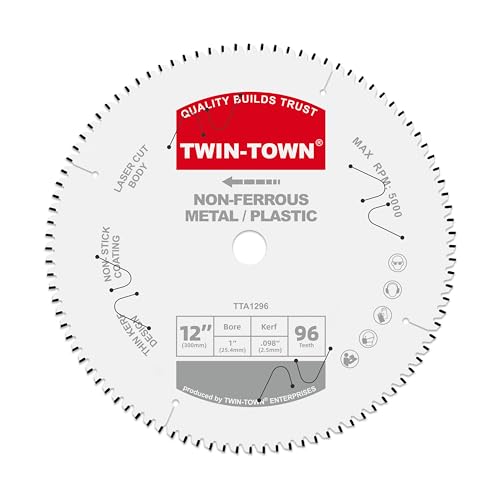

TWIN-TOWN 96 Tooth Aluminum Cutting Saw Blade (12-Inch)

With 96 ultra-fine carbide teeth and a -5-degree angle, TWIN-TOWN’s 12-inch blade delivers exceptional performance for craftsmen who work primarily with aluminum and non-ferrous metals.

You’ll appreciate the C4 grade carbide teeth that stay sharp twice as long as standard blades, while the electrophoretic coating prevents rust and corrosion. The TCG grind design guarantees clean cuts without burrs, making it perfect for aluminum shower doors, railings, and trim work.

Users consistently report excellent results when cutting 1/8″ aluminum and acrylic sheets. While it’s pricier for light-duty tasks, the blade’s lifetime warranty and unique ID tracking system justify the investment for serious metalworking projects.

Best For: Professional craftsmen and contractors who frequently work with aluminum, non-ferrous metals, and plastics, especially those specializing in shower doors, custom railings, and precision trim work.

Pros:

- Ultra-fine C4 carbide teeth stay sharp twice as long as standard blades

- TCG grind design produces clean, burr-free cuts in aluminum and non-ferrous metals

- Electrophoretic coating prevents rust and corrosion, extending blade life

Cons:

- Higher price point may not be justified for occasional or light-duty use

- Can be noisy if not properly balanced during operation

- Requires slower cutting speed to prevent material catching

MAZING 12 Inch Circular Saw Blade for Aluminum Cutting (100T)

Budget-conscious DIYers seeking quality aluminum cuts will find exceptional value in the MAZING 12-inch circular saw blade. With its 100 tungsten carbide teeth and triple chip grinding design, you’ll achieve smooth, burr-free cuts in aluminum and non-ferrous metals.

The blade features four extension slots for heat dissipation and operates at up to 5000 RPM. You’ll appreciate its versatility across various power tools, including miter saws, table saws, and chainsaws. While it’s priced lower than premium brands, users report performance that rivals more expensive options. The 2.9mm kerf and 5.8mm tooth height guarantee precise cuts for your aluminum projects.

Best For: Hobbyists and DIY enthusiasts who need a cost-effective solution for cutting aluminum and non-ferrous metals while maintaining acceptable quality standards.

Pros:

- Excellent value for money compared to premium brands

- Versatile compatibility with various power tools

- Effective heat dissipation through four extension slots

Cons:

- May not match the longevity of premium brand options

- Limited to non-ferrous metals and materials

- Higher tooth count (100T) may result in slower cutting speeds

DEWALT 12-inch Fine Finish Miter Saw Blade (DWA112100)

Professional craftsmen seeking exceptional cutting precision will appreciate the DEWALT DWA112100 12-inch blade. With its 100-tooth design and ultra-sharp carbide construction, you’ll achieve remarkably clean cuts on your projects.

The blade’s patented body slot design reduces vibration while cutting, and its optimized tooth geometry enhances accuracy. You’ll notice the blade’s exceptional stiffness, thanks to its precision tensioning that improves stability during operation. What’s more, you’ll get up to three times more life from this blade compared to standard options, making it a cost-effective choice for your fine finish cutting needs.

Best For: Professional woodworkers and contractors who need precise, clean cuts for trim work, cabinet making, and fine woodworking projects.

Pros:

- Ultra-sharp carbide teeth deliver exceptionally clean, precise cuts

- Patented design reduces vibration for improved accuracy

- Extended blade life (up to 3x longer) provides good value for money

Cons:

- Higher initial cost compared to standard blades

- 100-tooth design may cut slower than blades with fewer teeth

- May require more frequent cleaning due to fine-cut sawdust buildup

Factors to Consider When Choosing a 12″ Metal Cutting Blade for Miter Saw

When selecting a 12″ metal cutting blade for your miter saw, you’ll need to evaluate key factors like tooth count, tooth design, and blade material quality to guarantee peak cutting performance. You should verify the blade’s maximum speed rating matches your saw’s specifications and confirm it’s compatible with the specific metals you plan to cut. The blade’s kerf width will affect both the precision of your cuts and the amount of material waste, so choose according to your project requirements.

Tooth Count and Design

Selecting the right tooth configuration for your 12-inch metal cutting blade can dramatically impact cut quality and performance. You’ll want to choose a blade with 80 to 100 teeth for ideal results, as higher tooth counts deliver smoother cuts with minimal burrs.

For aluminum work, you’ll benefit from a Triple Chip Grind (TCG) tooth design, which creates clean, burr-free finishes essential for detailed projects. If you’re working with softer metals, consider an Alternating Top Bevel (ATB) design to boost cutting efficiency. Look for blades with thin kerf designs to reduce material waste during cuts.

Pay attention to the tooth geometry and hook angle configuration – these features affect how well your blade removes chips and manages heat while cutting, directly influencing your finished product’s quality.

Blade Material Quality

The material composition of your metal cutting blade determines its performance, durability, and value. You’ll want to focus on blades made from premium alloy steel with tungsten carbide tips (TCT), as they’re specifically designed to handle tough materials like aluminum and brass without losing their edge.

Look for blades featuring an electrophoretic coating, which provides essential protection against rust and corrosion, extending your blade’s lifespan. When examining blade options, pay attention to the kerf thickness – it should be appropriate for your cutting needs to minimize material waste. The blade’s tooth geometry, whether TCG or ATB, works in conjunction with the material quality to deliver clean, precise cuts. Quality materials guarantee your blade maintains its cutting efficiency and structural integrity through repeated use.

Maximum Speed Rating

Maximum speed ratings play an essential role in your blade selection process. When choosing a metal cutting blade for your miter saw, you’ll need to verify the blade’s RPM rating matches your saw’s capabilities. Most aluminum cutting blades operate safely at around 5000 RPM, which helps deliver smooth, efficient cuts through metal materials.

You’ll want to pay close attention to the maximum speed rating listed on the blade, as exceeding this limit can be dangerous. Operating a blade beyond its rated speed can cause it to deform, wear prematurely, or even break during use. For peak performance and safety, always check your miter saw’s specifications and select a blade with a compatible RPM rating. This will help you achieve cleaner cuts while maintaining the blade’s integrity and your safety.

Compatibility With Materials

Matching your blade to specific metal materials requires careful consideration of several key factors. When you’re working with aluminum and non-ferrous metals, look for blades with TCG or ATB tooth designs that are specifically engineered for these materials. You’ll want to choose a blade with a high tooth count of 96-100 teeth to achieve smooth, burr-free cuts in your metal workpieces.

The blade’s kerf thickness is essential for precision work – thinner kerfs create less waste and deliver cleaner cuts in aluminum. Make sure your blade features tungsten carbide teeth, as they’ll provide the heat resistance and durability needed for metal cutting applications. Don’t forget to verify the arbor size matches your miter saw, typically 1-inch for 12-inch blades.

Kerf Width Impact

Understanding kerf width is essential when selecting a metal cutting blade for your miter saw. You’ll want to take into account that thinner kerfs, typically between 2.5mm to 3mm, provide more precise cuts and create less waste when cutting metal. They’ll also require less power from your saw, making the cutting process more efficient.

While thin-kerf blades excel at detailed work and produce cleaner edges with minimal material deformation, they’re not always the best choice for every job. If you’re cutting thicker metal pieces, you might need a wider kerf blade to maintain stability during cuts. Remember that although wider kerfs are more durable for heavy-duty applications, they’ll slow down your feed rate and waste more material. Choose your blade’s kerf width based on the specific demands of your cutting tasks.

Heat Dissipation Features

Beyond blade thickness, heat management plays a key role in your metal cutting blade’s performance. When you’re cutting metal, your blade needs effective heat dissipation features to prevent overheating during extended use. Look for blades with extension slots or specialized coatings that help reduce thermal build-up.

These cooling features won’t just protect your blade – they’ll also improve your cutting accuracy and extend your blade’s lifespan. You’ll notice better chip removal and smoother cuts, as proper heat management prevents the blade from binding in dense materials. Many high-quality metal cutting blades incorporate design elements that promote airflow during operation. By choosing a blade with superior heat dissipation capabilities, you’ll achieve cleaner finishes and more consistent results in your metalworking projects.