You're on the brink of uncovering the finest advancements in 10-inch table saw blades for 2025. Picture yourself achieving unparalleled precision with blades featuring micrograin carbide and thin kerf designs. Top brands like CMT and DEWALT are setting new standards in cutting technology. Whether you're a woodworking enthusiast or a professional, these blades promise cleaner cuts and reduced waste. What's next in this cutting-edge journey? Let's explore.

key Takeaways

- CMT XTreme's 50-tooth blade offers smooth cuts on solid wood and laminates, ideal for precision woodworking.

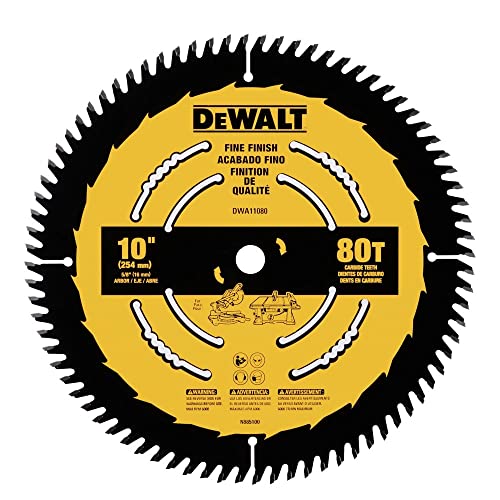

- DEWALT's 80-tooth blade delivers ultra-fine finishes on dense woods, suitable for detailed projects.

- Freud LU87R010 excels at fast ripping with minimal waste, enhancing precision on thicker materials.

- WEN's 80-tooth blade ensures clean, tear-out-free cuts, maintaining accuracy on hardwoods.

- DEWALT's 60-tooth combo pack provides versatile, long-lasting performance for both crosscutting and general purpose tasks.

CMT XTreme Industrial Combination Saw Blade, 10-Inch x 50 Teeth

If you're on the hunt for a versatile and high-performing table saw blade, the CMT XTreme Industrial Combination Saw Blade could be your best bet. With its 10-inch size and 50 teeth configuration, it handles solid wood, melamine, and laminates with ease. The micrograin carbide construction guarantees durability, while the laser-cut, hardened plate with expansion slots minimizes noise and vibration. Its thin kerf technology is perfect for underpowered saws, offering faster cuts and longer blade life. Plus, the anti-kickback design boosts safety. With a 4.8-star rating, users love its sharpness and smooth finishes, making it a top choice for precision cutting.

Best For: Woodworkers and DIY enthusiasts seeking a durable, versatile saw blade that provides precise, smooth cuts on wood and wood products.

Pros:

- Micrograin carbide construction ensures long-lasting durability and smooth cuts.

- Thin kerf technology is ideal for underpowered saws, allowing for faster cuts and extended blade life.

- Anti-kickback design enhances safety during operation.

Cons:

- Some users have reported issues with blade alignment, potentially due to saw arbor compatibility.

- Occasional noise concerns have been noted, although often attributed to factors other than blade quality.

- Requires proper maintenance and resharpening for optimal performance.

DEWALT 10-Inch Miter/Table Saw Blades Combo Pack (DW3106P5)

Among the standout features of the DEWALT 10-Inch Miter/Table Saw Blades Combo Pack (DW3106P5) is its versatility, making it an ideal choice for both professional woodworkers and DIY enthusiasts. This combo includes a 60-tooth fine-finish blade and a 32-tooth general purpose blade, perfect for various materials like softwood, hardwood, chipboard, and plywood. You'll appreciate the tough tungsten carbide construction, ensuring sharpness and durability. The thin kerf design offers fast, smooth cuts, while the computer-balanced plate minimizes vibration for precision. Customers rave about its performance and value, often comparing it favorably to pricier brands.

Best For: Professional woodworkers and DIY enthusiasts looking for versatile and durable saw blades for various cutting applications.

Pros:

- Tough tungsten carbide construction ensures long-lasting sharpness and durability.

- Thin kerf design allows for fast and smooth cutting with minimal debris.

- Computer-balanced plate reduces vibration, enhancing precision and finish quality.

Cons:

- May not be suitable for cutting metal or non-wood materials.

- Some users may find the 32-tooth blade less effective for fine finishes.

- The combo pack may be more than necessary for casual or infrequent users.

DEWALT Table Saw Blade, 10 inch, 80 Tooth, Fine Finish (DWA11080)

The DEWALT Table Saw Blade, 10 inch, 80 Tooth, Fine Finish (DWA11080) stands out as a top choice for those seeking exceptional cutting precision and longevity. You'll appreciate its ultra-sharp carbide tips and optimized tooth geometry, ensuring clean, crisp cuts on plywood and maple veneer. Its patented body slot design minimizes vibration, enhancing both performance and blade life. Users consistently praise its ability to deliver flawless edges on dense woods and vinyl flooring. While some find it dulls quickly on tougher materials and note discrepancies in appearance, many recommend it as a cost-effective alternative to pricier blades like Diablo.

Best For: Individuals seeking a table saw blade that provides exceptional cutting precision and clean finishes on plywood, maple veneer, and dense woods.

Pros:

- Ultra-sharp carbide for crisp, clean cuts

- Patented body slot design for reduced vibration

- Cost-effective alternative to pricier blades

Cons:

- Dulls quickly on tougher materials like laminate

- Discrepancies between product image and actual design

- Mixed reviews regarding longevity and durability

DEWALT 10" Table Saw Blade (40 Tooth, Fine Finish)

Consider the DEWALT 10" Table Saw Blade with 40 teeth for woodworkers seeking precision and durability without breaking the bank. This blade offers clean cuts with its ultra-sharp carbide-tipped teeth, boasting a lifespan up to three times longer than standard blades. You'll appreciate its optimized tooth geometry and thin kerf design, which guarantee smooth performance and accuracy. Whether you're ripping hard maple with minimal burn marks or making smooth cross cuts, this blade competes with high-end brands. Many users praise its excellent value and reliability, making it a top choice for both casual and serious woodworking projects.

Best For: Woodworkers seeking a reliable and durable table saw blade that offers high performance and precision without the premium price tag.

Pros:

- Offers up to 3X longer lifespan with ultra-sharp carbide-tipped teeth.

- Comparable in cut quality to high-end blades but at a lower price.

- Ideal for both ripping and cross-cutting with minimal burn marks.

Cons:

- Slight splintering may occur without a backing board during cross cuts.

- Not as premium as some high-end brands for those seeking the absolute best finish.

- May not be suitable for those exclusively looking for a blade with more than 40 teeth for finer work.

WEN 10-Inch 80-Tooth Carbide-Tipped Saw Blade for Miter & Table Saws

If you're a woodworking enthusiast seeking precision and smooth finishes, the WEN 10-Inch 80-Tooth Carbide-Tipped Saw Blade is a standout choice. It's designed for clean, ultra-fine cuts with its ultra-thin 1/10-inch kerf. Whether you're working with hardwoods like oak or softer woods like pine, this blade excels, leaving minimal tear-out and requiring little sanding. Its compatibility with most miter and table saws, combined with stability and vibration resistance, guarantees precise, wobble-free cuts. Users love its affordability and durability, often buying multiple blades. It's perfect for trim work, cabinetry, and delicate tasks, making it essential for pros and DIYers alike.

Best For: Woodworking enthusiasts and professionals seeking precision and smooth finishes for a variety of projects, including trim work and cabinetry.

Pros:

- Provides clean, ultra-fine cuts with minimal tear-out.

- Affordable price encourages multiple purchases.

- Compatible with most miter and table saws for versatile use.

Cons:

- May require frequent sharpening with extensive use.

- Limited to 10-inch saw compatibility.

- Not ideal for cutting metal or non-wood materials.

Freud LU83R010: 10 Thin Kerf Combination Blade

Are you a woodworker seeking a versatile blade that combines precision with efficiency? The Freud LU83R010 10-Inch Thin Kerf Combination Blade might be your perfect match. With a 5/8-inch arbor and 50 teeth, this blade excels in both ripping and crosscutting, thanks to its flat-top raker and alternating-top-bevel teeth. Its .091-inch thin kerf allows for smooth, fast cuts with less power. High-density carbide guarantees edge retention, while Perma-SHIELD coating minimizes friction. Enhanced by laser-cut anti-vibration slots, you'll enjoy quieter, more accurate cuts. Suitable for various materials, it's praised for clean results and backed by a limited lifetime warranty.

Best For: Woodworkers seeking a versatile, efficient blade for both ripping and crosscutting tasks with minimal noise and high precision.

Pros:

- Thin kerf design allows for smooth and fast cuts with less power.

- High-density carbide and Perma-SHIELD coating provide excellent edge retention and reduced friction.

- Anti-vibration technology enhances cutting accuracy and reduces noise.

Cons:

- May not be suitable for extremely thick materials beyond its specified capacity.

- Thin kerf blades can sometimes flex, requiring careful use to maintain accuracy.

- Premium features may come at a higher price point compared to basic blades.

3-Pack Woodworking Saw Blades Combo (32T, 60T, 80T)

For woodworkers seeking versatility and high-quality results, the Pack Woodworking Saw Blades Combo (32T, 60T, 80T) is an excellent choice. This 3-pack features 10-inch blades tailored for different tasks: 32T for general purposes, 60T for fine finishes, and 80T for ultra-fine finishes. They're perfect for cutting softwood, hardwood, and laminated materials. With a thin 0.095 kerf and alternating top bevel teeth, you'll achieve smooth, accurate cuts while minimizing waste. The blades' tungsten carbide teeth guarantee long-lasting sharpness. Compatible with most 10-inch saws, users praise their quality and performance, making them a smart addition to your workshop.

Best For: Woodworkers seeking a versatile, high-quality saw blade set for various woodworking tasks and materials.

Pros:

- Versatile combo for general, fine, and ultra-fine finishes.

- Tungsten carbide teeth ensure long-lasting sharpness.

- Compatible with most 10-inch miter, jobsite, and table saws.

Cons:

- May require frequent cleaning to maintain optimal performance.

- Limited to 10-inch saw blade compatibility only.

- Not ideal for cutting metal or non-wood materials.

Freud LU87R010: 10 Thin Kerf Rip Blade

Freud's LU87R010 Thin Kerf Rip Blade stands out for woodworkers seeking efficiency and precision in their projects. With its 10-inch diameter and 5/8-inch arbor, this blade packs 24 teeth with a flat grind and 20° hook angle, making it ideal for ripping hard and softwoods. The thin kerf design guarantees faster feed rates and less material waste. Thanks to the premium TiCo HI-Density Carbide, you'll enjoy long-lasting performance. The anti-vibration feature reduces noise and improves cut quality. Plus, the Perma-SHIELD coating minimizes heat and pitch buildup, extending the blade's life and reducing maintenance downtime.

Best For: Woodworkers seeking efficient and precise ripping of hard and softwoods with minimal waste and long-lasting blade performance.

Pros:

- Premium TiCo HI-Density Carbide for enhanced durability and performance.

- Thin Kerf design enables faster feed rates and less material waste.

- Anti-vibration feature ensures cleaner cuts and reduced noise.

Cons:

- May experience surface finish loss when cutting outside the ideal range.

- Not specifically designed for crosscutting tasks.

- Some users may require additional safety measures when ripping with a table saw.

DEWALT Miter and Table Saw Blade Combo (2-Pack, 40T and 60T)

DEWALT's Miter and Table Saw Blade Combo (2-Pack, 40T and 60T) stands out for woodworkers seeking precision and durability without breaking the bank. With ultra-sharp, carbide-tipped teeth and optimized geometry, these blades promise clean cuts and up to three times the lifespan*. The 60T blade excels at crosscutting, ensuring smooth, tear-free cuts, while the 40T blade handles general purposes effortlessly. Users rave about their ability to cut various materials like pine boards with minimal resistance. These blades offer exceptional value, performing on par with pricier alternatives, making them a savvy choice for anyone needing reliable cutting solutions.

Best For: Woodworkers looking for precision, durability, and affordability in saw blades without compromising performance.

Pros:

- Ultra-sharp carbide-tipped teeth ensure clean cuts.

- Offers up to 3X the lifespan compared to standard blades.

- Provides excellent value with performance comparable to higher-priced alternatives.

Cons:

- Performance may vary if cutting conditions aren't monitored.

- May not be ideal for materials other than wood.

- Limited to 10-inch saws only.

WEN 10-Inch Fine-Finish Woodworking Saw Blade (BL1060)

The WEN 10-Inch Fine-Finish Woodworking Saw Blade (BL1060) stands out as an excellent choice for woodworking enthusiasts seeking precision and affordability in their tools. With 60 carbide-tipped teeth, it's perfect for achieving clean, fine cuts on both hard and softwoods like oak and maple. Its ultra-thin kerf guarantees efficiency, while heat expansion slots maintain accuracy. Compatible with most 10-inch saws, this blade's lightweight design enhances your cutting experience. Users rave about its durability and performance, even when compared to pricier brands. Plus, with a 4.7-star rating from over 2,300 reviews, you know you're making a reliable choice.

Best For: Woodworking enthusiasts seeking precision, durability, and affordability in their cutting tools.

Pros:

- 60 carbide-tipped teeth designed for clean, fine-finish cuts on various woods

- Ultra-thin kerf for efficient and precise cutting

- High user ratings with positive feedback on performance and value for money

Cons:

- Limited to use with 10-inch saws only

- May require more frequent sharpening compared to higher-end blades

- Protective coating might not fully prevent gumming in heavy-duty use

Factors to Consider When Choosing a 10 Inch Table Saw Blade

When you're choosing a 10-inch table saw blade, it's essential to take into account several key factors to guarantee peak performance. Pay attention to the blade tooth count, material and coating, kerf thickness, hook angle, and tooth geometry, as each affects your cutting precision and efficiency. Understanding these elements will help you select the right blade for your specific woodworking needs.

Blade Tooth Count

While selecting a 10-inch table saw blade, considering the blade's tooth count is essential. A lower tooth count, like 32 teeth, is perfect for quick, rough cuts, ideal when speed trumps finish quality. If you're after a smoother, finer finish, opt for a higher tooth count, such as 80 teeth. Blades with 40 to 60 teeth strike a balance and are versatile enough for both ripping and crosscutting tasks, making them great general-purpose options. Additionally, a higher tooth count often means a thinner kerf, minimizing material waste and improving efficiency—especially beneficial for underpowered saws. The tooth design, like Alternate Top Bevel (ATB), also influences performance, with ATB being better suited for precise crosscuts.

Material and Coating

Selecting the right material and coating for your 10-inch table saw blade can make a big difference in cutting performance and durability. High-density or micrograin carbide materials are your go-to for superior edge retention and a longer lifespan, outlasting standard steel blades. Opt for blades with non-stick or anti-friction coatings to minimize friction and heat, effectively reducing resin buildup that can dull your blade. This means your blade stays sharper longer and requires less maintenance. Consider blades with anti-vibration features like heat expansion slots for smoother operation and less noise, which enhance your cutting experience. These design elements guarantee you get precise cuts with minimal effort, making your table saw more efficient and reliable in the long run.

Kerf Thickness

Understanding kerf thickness is essential when choosing a 10-inch table saw blade because it directly influences cutting efficiency and material waste. A blade's kerf, or cut width, determines how much material gets removed. Opting for a thin kerf blade, usually around 0.094 inches, minimizes waste and suits underpowered saws, making cuts faster and requiring less power. These blades are perfect for precision and fine-finish work, as they reduce material loss and tear-out risk. However, it's important to match kerf thickness to the material's thickness; thicker materials might need a wider kerf to avoid binding issues. Standard kerf thickness ranges from 0.091 to 0.098 inches, so choose wisely based on your cutting needs and saw power.

Hook Angle

When choosing a 10-inch table saw blade, one essential factor to contemplate is the hook angle, which plays a significant role in the blade's cutting action and efficiency. The hook angle determines how aggressively the blade engages with the material. A higher hook angle, like 20°, offers aggressive cutting, perfect for ripping through hardwoods quickly. On the other hand, a lower hook angle, around 10°, is ideal for crosscutting softer materials, reducing kickback risks and guaranteeing smoother cuts. You'll find that selecting the right hook angle directly impacts the blade's performance, affecting speed, smoothness, and the potential for splintering, particularly with delicate materials. Understanding the hook angle guarantees you choose the best blade for your specific woodworking tasks, balancing quality and safety.

Tooth Geometry

Tooth geometry is a fundamental factor in optimizing your table saw blade's performance. It dictates how well your blade handles different tasks. For instance, an Alternate Top Bevel (ATB) configuration excels at crosscutting, while a Flat Top Raker (FT) is better for ripping wood. A higher tooth count, like 60 or 80 teeth, gives you smoother cuts, perfect for delicate materials such as plywood and veneer.

Consider the hook angle, too; a larger angle (20°) speeds up cutting but can leave rough edges. A smaller angle (10°) provides smoother finishes. Also, the kerf width impacts material removal. Thinner kerf blades are efficient for underpowered saws, requiring less power and producing less waste. Proper tooth geometry also helps minimize kickback, enhancing safety.

Vibration Reduction

After considering tooth geometry, let's focus on vibration reduction, an essential factor for smooth, accurate cuts and minimizing fatigue. High-quality blades often feature anti-vibration technology, like laser-cut slots, to dampen vibrations and enhance cutting performance. This technology helps maintain precision and reduces the risk of splintering. You'll want a blade with a balanced design to prevent wobbling, ensuring cleaner cuts. Thin kerf blades are also beneficial as they require less power, promoting a smoother operation. Remember, proper maintenance and alignment of your table saw are vital in optimizing vibration reduction. Keeping your equipment in top shape lets the blade perform at its best and extends its lifespan. Choose wisely, and enjoy the benefits of reduced vibration in your work.

Cutting Applications

Selecting a 10-inch table saw blade involves considering several essential factors to confirm peak performance for your specific cutting applications. First, examine the tooth configuration. Designs like Alternate Top Bevel (ATB) or Flat Grind influence whether you're ripping or crosscutting. Next, focus on kerf thickness; thinner blades, ranging from 0.091 to 0.1 inches, minimize waste and enhance precision. Verify compatibility with materials—hardwoods, softwoods, plywood, or laminates—to achieve a high-quality finish. Also, consider the hook angle; a higher angle boosts cutting speed but can cause tear-out on delicate materials. Finally, check the maximum RPM rating. It should match or exceed your table saw's speed, confirming safe, efficient operation. These considerations help tailor your blade choice to your cutting needs.

Durability and Longevity

While choosing the right 10-inch table saw blade for specific cutting applications is essential, understanding the factors affecting its durability and longevity guarantees you get the most out of your investment. High-density carbide is key, offering excellent edge retention and a longer cutting life. Opt for blades with a thin kerf design; they require less power, reducing wear on the blade and saw. Consider blades that can handle nails or wood imperfections, preventing chipping and dulling. Anti-vibration technology is vital, as it minimizes chatter, enhancing both cutting accuracy and blade life. Don't forget regular maintenance; resharpening and cleaning extend the blade's lifespan, ensuring it performs consistently across many tasks. Each of these factors contributes to a blade's long-lasting performance.