If you're in the market for a thin kerf table saw blade that promises precision cuts in 2025, you're in the right place. With options like the Freud LU87R010 for ripping and the LU88R010 for fine crosscuts, there's a perfect blade for every woodworking task. But that's not all—some blades offer versatility and affordability too. Curious about which ones? Let's explore the features and benefits that make these blades stand out.

key Takeaways

- Freud LU88R010 provides precision crosscuts with its 60 teeth and non-stick coating, ensuring minimal waste in woodworking projects.

- FOXBC 10-Inch Ultra Finish Blade offers exceptional value with 80 teeth for smooth, quiet cuts across various wood types.

- CMT XTreme Industrial Blade features a 50-tooth design and anti-kickback safety, ideal for versatile and safe cutting applications.

- Freud LU87R010 excels in ripping tasks with its thin kerf and carbide blend for faster, efficient hardwood and softwood cuts.

- Freud LU86R010 offers excellent versatility and value with a 40-tooth design, suitable for both ripping and crosscutting tasks.

Freud LU87R010: 10 Thin Kerf Rip Blade

If you're looking for a high-quality blade for your table saw, the Freud LU87R010: 10 Thin Kerf Rip Blade is a standout choice. With its 10-inch diameter and 5/8-inch arbor, this blade features a flat grind and a 20° hook angle, perfect for ripping hardwoods and softwoods. Its premium TiCo HI-Density Carbide Ripping Blend guarantees durability and performance. The thin kerf design allows for faster feed rates, reducing waste. You'll appreciate the large tooth design, which permits multiple sharpenings, extending the blade's life. Its anti-vibration and Perma-SHIELD coating reduce noise, drag, and heat, guaranteeing smooth, efficient cuts.

Best For: Woodworkers looking for a high-performance rip blade that ensures efficient, smooth cuts on both hardwoods and softwoods with reduced waste.

Pros:

- Premium TiCo HI-Density Carbide ensures durability and excellent performance.

- Thin kerf design allows for faster feed rates and reduced waste.

- Anti-vibration and Perma-SHIELD coating reduce noise, drag, and heat buildup.

Cons:

- May experience some surface finish loss on chipboard or laminates outside the ideal range.

- Requires careful handling and maintenance to ensure prolonged blade life.

- Limited lifetime warranty may not cover all types of damage or wear.

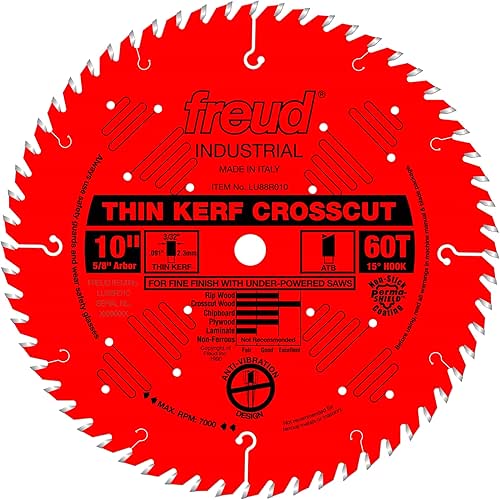

Freud LU88R010: 10 Thin Kerf Fine Finish Crosscut Blade

The Freud LU88R010 10 Thin Kerf Fine Finish Crosscut Blade stands out with its premium TiCo HI-Density Carbide Crosscutting Blend, making it the perfect choice for woodworkers seeking precision and efficiency. With a 5/8 arbor, 10-inch diameter, and 60 teeth, this blade excels in delivering smooth finishes on materials like mahogany plywood and hard maple. Its thin kerf design minimizes waste and guarantees easier feeding. The Perma-Shield Non-Stick Coating reduces drag and prevents corrosion. Users appreciate its quiet operation and superior performance compared to older blades. While some see it as pricey, its quality and versatility make it worth the investment.

Best For: Professional woodworkers and hobbyists seeking high-quality, precise cuts with minimal waste and effort.

Pros:

- Premium TiCo HI-Density Carbide for maximum performance and durability

- Thin kerf design reduces material waste and allows for easier feeding

- Perma-Shield Non-Stick Coating minimizes blade drag and protects against corrosion

Cons:

- Considered pricey compared to other blades

- May require bore enlargement for compatibility with specific saw models

- Primarily intended for crosscutting, with limited effectiveness for larger rip cuts

FOXBC 10-Inch Ultra Finish Table Saw Blade (80-Tooth)

Looking for a versatile and high-performance table saw blade? The FOXBC 10-Inch Ultra Finish Blade, with its 80 teeth and 0.098 kerf, is a top choice. It handles oak, pine, melamine, and more with ease, offering smooth, quiet cuts and zero tear-out. Made from high-density tungsten carbide, it's tough and wear-resistant, outperforming pricier brands like Diablo. Compatible with major saw brands, it's an affordable option praised for its precision and value. Users love the sanded-edge finish, though some note burn marks on hardwood after heavy use. It's perfect as both a primary and temporary blade solution.

Best For: Woodworkers and DIY enthusiasts looking for an affordable, high-performance table saw blade compatible with major brands for smooth and precise cuts.

Pros:

- High-density tungsten carbide construction for enhanced durability and wear resistance.

- Smooth, quiet cuts with zero tear-out, ideal for various wood types.

- Outperforms more expensive brands, offering excellent value for money.

Cons:

- Some users report burn marks on hardwood after extensive use.

- Diameter accuracy may require spacers for complete cuts on certain miter saws.

- May not be suitable for professional use as a long-term primary blade.

CMT XTreme Industrial Combination Saw Blade, 10-Inch x 50 Teeth

For woodworking enthusiasts exploring the domain of thin kerf table saw blades, the CMT XTreme Industrial Combination Saw Blade stands out as an exceptional choice. Its 10-inch, 50-tooth design (4 ATB + 1 flat grind) guarantees smooth, precise cuts on various materials like wood, melamine, and chipboard. The micrograin carbide construction enhances durability, while the thin kerf technology reduces saw load, making it ideal for underpowered saws. With a 15° hook angle, this blade delivers efficient, fast cuts. You'll appreciate its anti-kickback design and tri-metal brazing, which boost safety and performance, backed by a robust warranty and customer satisfaction.

Best For: Woodworking enthusiasts and professionals seeking a durable, high-performance saw blade for precise and efficient cuts on various wood materials and laminates.

Pros:

- Durable micrograin carbide construction for long-lasting sharpness.

- Thin kerf technology reduces load on saws, ideal for underpowered models.

- Anti-kickback design enhances safety during operation.

Cons:

- Some users have reported alignment issues, potentially due to saw arbor rather than blade quality.

- Occasional blade noise may occur, possibly linked to improper installation.

- Requires proper resharpening to maintain optimal performance over time.

Freud LU86R010: 10 Thin Kerf General Purpose Blade

If you need a versatile and budget-friendly blade that excels in both rough and fine woodworking, Freud's LU86R010 is a top contender. With a 10-inch diameter and 40 ATB teeth, it handles clean rips and crosscuts with ease. Its .094-inch kerf and .071-inch plate guarantee stability and precision. The 13° hook angle aids in fast cutting, while the Perma-Shield coating prevents drag and corrosion. Its premium TiCo carbide teeth promise long life, even after resharpenings. Priced under $50, it offers outstanding value, making it perfect for both DIY enthusiasts and professionals seeking reliability without breaking the bank.

Best For: DIY enthusiasts and professionals seeking a versatile and cost-effective saw blade for both rough and fine woodworking tasks.

Pros:

- Durable with a long-lasting sharpness due to premium TiCo carbide teeth.

- Perma-Shield coating reduces drag and protects against corrosion.

- Priced under $50, offering excellent value for money.

Cons:

- Occasional rough cuts in specific scenarios.

- Users may need to purchase multiple blades for extensive use.

- Thin kerf design may not be suitable for all heavy-duty projects.

Factors to Consider When Choosing a Table Saw Blade Thin Kerf

When choosing a thin kerf table saw blade, pay attention to the blade's material quality, as it affects durability and performance. Consider the teeth count—it influences the smoothness and speed of your cuts. Don't forget to evaluate the coating benefits and guarantee the blade's application suitability for your projects while prioritizing safety considerations.

Blade Material Quality

Choosing the right table saw blade involves understanding the quality of the blade material, which plays an essential role in performance and durability. Opt for blades made from micrograin carbide—they're durable, resist wear, and excel at cutting hard materials. Look for an alloy composition, often with titanium, to guarantee sharpness retention and chip resistance. A laser-cut plate enhances precision and stability, reducing vibration for smoother cuts. Pay attention to the blade's Rockwell hardness rating; a range of 46-48 guarantees it withstands frequent use without dulling. Finally, consider the brazing process used to attach carbide teeth. Tri-metal brazing offers superior strength and fatigue resistance, extending the blade's lifespan and maintaining performance. Choose wisely for precision and longevity.

Teeth Count Importance

The teeth count on a table saw blade is an essential factor that directly influences the quality of your cuts. More teeth mean smoother finishes and reduced tear-out, especially on hardwoods and plywood. If you're ripping, a blade with around 24 teeth offers faster cuts. For crosscutting, opt for blades with 60-80 teeth for precision. Be aware that more teeth can cause increased friction and heat, requiring slower feed rates to avoid burning the material. When choosing, balance the cut quality you desire with the material type. Thicker materials often benefit from fewer teeth to ease the saw's strain. For versatile use, a 40-tooth blade is a great compromise, handling both ripping and crosscutting effectively.

Coating Benefits

Considering a table saw blade's coating can greatly enhance your cutting experience. A non-stick coating, like Perma-SHIELD, reduces blade drag, ensuring smoother operation with less resistance. This means you can enjoy faster feed rates and cleaner cuts. Coatings also help minimize heat buildup, prolonging the blade's life and maintaining sharpness longer. You'll appreciate how coatings protect against corrosion and pitch build-up, cutting down on maintenance and keeping downtime minimal. This protection also boosts efficiency, as less pitch build-up allows the blade to perform better across various materials. By selecting a blade with a quality coating, you're making a choice that enhances performance while reducing the need for frequent cleaning and sharpening, ultimately saving you time and effort.

Application Suitability

While coatings play a vital role in enhancing blade performance, understanding the application suitability of thin kerf table saw blades guarantees you get the most out of your woodworking projects. These blades excel in tasks requiring faster feed rates and less material waste, perfect for both ripping and crosscutting. They handle materials from 3/4 inch to 2-3/4 inches thick, making them versatile for various projects. With their design, you'll enjoy smoother cuts with less resistance, leading to improved accuracy and cleaner finishes. They're particularly effective for cutting plywood or laminates, minimizing tear-out and surface damage. However, be mindful of potential blade flex when working with thicker materials, as it can impact cut quality and precision. Choose wisely for best results.

Safety Considerations

Choosing the right table saw blade isn't just about performance—safety should be a top priority. With around 7 accidents daily in the U.S., selecting safe blades is essential. Thin kerf blades can enhance safety by reducing motor drag, improving control and stability during cuts. This is critical for precision and preventing mishaps. Look for blades with anti-vibration designs; they guarantee cleaner cuts and lower noise levels, minimizing distractions and creating a safer workspace. Although radial arm saws offer better dust collection and effective blade guards, proper blade maintenance is key regardless of equipment. Keeping blades clean and reducing pitch buildup prevents unexpected failures. Prioritize these safety features when choosing your next table saw blade to protect yourself and achieve precision.